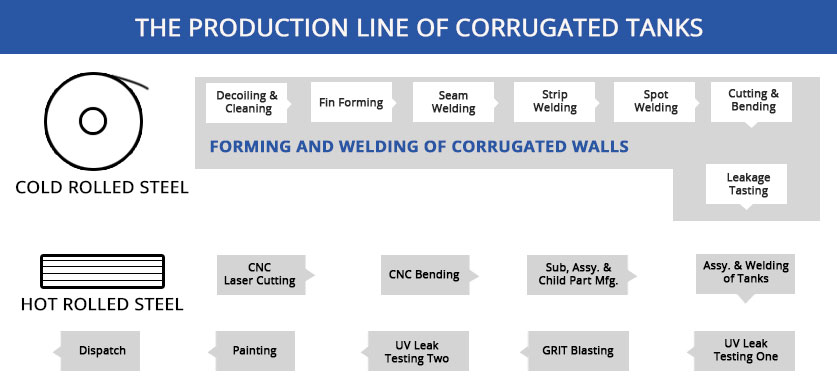

The tank is manufactured with cooling fins using a special cold rolled coil of 1 to 1.5 mm thickness.

- These fins have a sufficient degree of elasticity to absorb expansion involume of the liquid (insulating oil) and at the same time they provide a large surface area to dissipate the heat generated.

- The steel thickness and the fin depth, combined with the steel wall height determine the fin elasticity and pressure with standing capacity of the tank.

- Oil-saving, material-saving, economic and efficient to reduce your working cost.

- Good Cooling performance.

- Customized Corrugated panels are available as per customer’s requirement.

- Short delivery time

Tank and cover:

The sides of the tank are made of corrugated cooling surfaces. The bottom plate, side and frames are of a welded construction. The welds are tested for oil tightness. The thermometer pockets, bushings, tap switch drive and lifting lugs are fitted on the tank cover. The cover is bolted or welded to the tank frame & additional cable boxes can be provided for LV & HV connections on the sides. The under carriage is welded to the bottom plate.

Painting and surface treatment:

All metal parts are carefully grit blasted. The painting is done in accordance with ISO 12944 Global Corrosion Standards;

| SYSTEM | ENVIRONMENT | DESCRIPTION | SURFACE TREATMENT | PRIMER BASE COAT | PRIMER FIRST INTERMEDIATE COAT | PRIMER SECOND INTERMEDIATE COAT | TOP FINAL COAT | TOTAL DFT |

|---|---|---|---|---|---|---|---|---|

| C | C3 | Industrial atmospheres. high humidity areas | GRIT BLASTING | ZINC PHOSPHATE PRIMER- 60 MICRONS | EPOXY MIO PRIMER- 60 MICRONS | NA | POLYURETHANE TOP COAT- 40 MICRONS | 160 MICRONS |

| D | C4 | Power Chemical Plants | GRIT BLASTING | EPOXY ZINC PHOSPHATE PRIMER- 60 MICRONS | EPOXY MIO PRIMER- 60 MICRONS | EPOXY MlO PRIMER- 60 MICRONS | POLYURETHANE TOP COAT- 40 MICRONS | 220 MICRONS |

| E | C5I | Industrial areas with high humidity aggressive atmospheres. | GRIT BLASTING | EPOXY ZINC RICH PRIMER-50 MICRONS | EPOXY ZINC PHOSPHATE PRIMER-60 MICRONS | EPOXY MlO PRIMER-120 MICRONS (TWO COATS) | POLYURETHANE TOP COAT- 40 MICRONS | 270 M1CRONS |

| F | C5M | Marine off shore, costal areas with high salinity | GRIT BLASTING | EPOXY ZINC RICH PRIMER- 100 MICRONS | EPOXY ZINC PHOSPHATE PRIMERS 60 MICRONS | EPOXY MIO PRIMER-120 MICRONS (TWO COATS) | POLYURETHANE TOP COAT- 40 MICRONS | 320 MICRONS |

Note : Application of paint is by flow method to ensure full paint coverage.

Internal Coating of Tanks:

The tank is internally coated with reinforced PVB single pack primer which is fast drying and offers superior adhesion along with very good resistance to solvents, oil, grease & withstanding temperature upto 200º C