TANK TECHNICAL FEATURES

Corrugated fins manufactured on fully

automatic machines with an accuracy of ±1mm.

Seam welding done on corrugated fins with latest

fronius welding machines.

Cutting done on cnc laser cutting

Bending done on fully automatic

amada cnc bending machine

All tanks undergo a 100% pressure and uv test before and after

grit blasting to ensure leakproofness

Tanks are grit blasted to sa 2 1/2 with a grit

blasting profile of 50-70 microns.

All tanks are flow coated with epoxy two pack paints in

accordance with iso 12944 global corrosion standards.

Flow coating ensures that the paint reaches

hard to reach points of the tank

&

guarantees the minimum paint thickness on all tank surfaces..

All tanks are internally flushed with solvent

prior to internal painting to ensure no oil

or

foreign particles are present in the tanks & internally

coated with hot oil resistant paint.

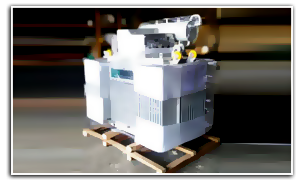

Packing configuration is such that all

accessories of the tank are packed on one pallet.